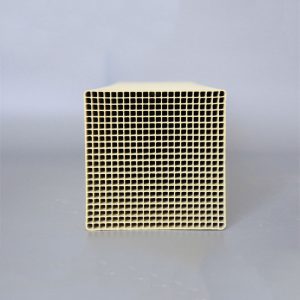

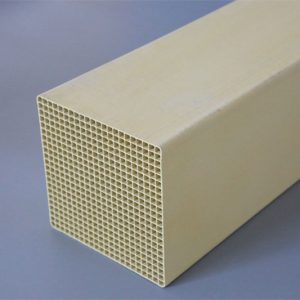

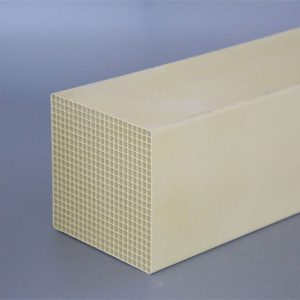

Ultra-High Temperature SCR Denitrification Catalyst–For Cement Industry High Strength Anti-Washout And Large Pore Size Anti-Clogging

Cement Industry use Catalyst

Why Choose Yuanchen Catalysts?

1. Industry Expertise:

Yuanchen DeNox honeycomb catalysts are tailored to the specific challenges faced by the cement industry, ensuring optimal performance and results.

2. Environmental Responsibility:

By reducing NOx emissions, our catalysts contribute to a greener and more sustainable cement production process.

3. Compliance Assurance:

Our catalysts are designed to meet or exceed stringent emissions standards, helping cement plants meet regulatory requirements.

4. Longevity and Durability:

Engineered for durability, our catalysts offer extended operational lifespans, minimizing maintenance and downtime.

Production line on Yuanchen Factory workshop:

|

|

|

DeNOx Honeycomb Catalyst Working Principle:

The Cement Industry Use DeNOx Catalyst is primarily employed within cement plants in conjunction with Selective Catalytic Reduction (SCR) systems. These systems are essential for reducing nitrogen oxide (NOx) emissions from the flue gases generated during cement production. Here’s how the process works:

Cement Kiln:

In a cement plant, a cement kiln is used to heat raw materials at high temperatures to produce clinker, which is the main component of cement. This process involves the combustion of fuels like coal, natural gas, or alternative fuels.

Flue Gas Treatment:

After combustion in the cement kiln, the flue gases produced contain various pollutants, including NOx. These gases are directed through a flue gas treatment system before being released into the environment.

Selective Catalytic Reduction (SCR) System:

Seamlessly integrating with cement plants, the SCR system complements the Cement Industry Use DeNOx Catalyst. This system is a pivotal component of the emissions control process, driving a chemical transformation that converts NOx gases into harmless nitrogen (N2) and water vapor (H2O).

Catalytic Reaction Enhancement:

At the heart of the SCR system, the Cement Industry Use DeNOx Catalyst plays a key role in accelerating the reduction of NOx emissions. The controlled introduction of ammonia (NH3) or urea initiates a reaction upstream of the catalyst. Within this catalytic environment, NOx reacts with ammonia, producing nitrogen and water vapor.

Promoting Emission Transformation:

Through the SCR process’s intricate orchestration, a substantial proportion of NOx emissions is systematically transformed. This transformative journey aids cement plants in maintaining regulatory compliance and fostering an atmosphere of cleaner air quality.

|

Main Specifications of Honeycomb DeNOx Catalyst:

| Hole Numbers (PCS) | Cross Section (mm) | Hole Diameter. (mm) | Wall Thickness (mm) | Catalyst Pitch (mm) | Open Porosity (%) | Specific Surface Area (㎡/m³) | Application |

| 15 × 15 | 150 × 150 | 8.45 | 1.35 | 9.80 | 71.40 | 338 | Coal fired unit, high smoke dust |

| 16 × 16 | 150 × 150 | 8.00 | 1.20 | 9.20 | 72.82 | 383 | |

| 18 × 18 | 150 × 150 | 7.10 | 1.10 | 8.20 | 72.60 | 409 | Coal fired unit, medium dust |

| 20 × 20 | 150 × 150 | 6.40 | 1.00 | 7.40 | 72.82 | 469 | |

| 21 × 21 | 150 × 150 | 6.10 | 0.95 | 7.05 | 72.93 | 478 | Coal fired unit, low smoke dust |

| 22 × 22 | 150 × 150 | 5.80 | 0.90 | 6.70 | 72.36 | 499 | |

| 25 × 25 | 150 × 150 | 5.00 | 0.90 | 5.90 | 69.44 | 577 | Coal fired unit, very low dust |

| 30 × 30 | 150 × 150 | 4.10 | 0.80 | 4.90 | 67.24 | 693 | Oil fired unit, very low dust |

| 35 × 35 | 150 × 150 | 3.65 | 0.55 | 4.20 | 72.53 | 795 | |

| 40 × 40 | 150 × 150 | 3.20 | 0.50 | 3.70 | 72.82 | 910 | Natural gas fired unit |

| 45 × 45 | 150 × 150 | 2.78 | 0.50 | 3.28 | 69.56 | 1000 | |

| 55 × 55 | 150 × 150 | 2.20 | 0.50 | 2.70 | 65.07 | 1275 | |

| Single Catalyst Size: 150 × 150 × (length 300~1350) mm. | |||||||

According to the customer’s requirements, we can produce different pitch and formulations of honeycomb SCR de NOx catalyst.

|

|

|

|

|

Related Products

-

Ultra-high Temperature SCR Denitrification Catalyst–For Industrial Coal Economiser Air Preheater

-

Ultra-high Temperature SCR Denitrification Catalyst–For Coal-fired Thermal Power Plants

-

Ultra-high Temperature SCR Denitrification Catalyst–For Anti-blocking dust power plants

-

Ultra-high Temperature SCR Denitrification Catalyst–Gas Turbine Boiler Denitrification

-

Ultra-high Temperature SCR Denitrification Catalyst–For Space-Limited Generator Furnaces

-

Ultra-High Temperature SCR Denitrification Catalyst–For Power Plants Low Emissions

-

SCR Denitrification Catalyst–For Coal Fired Boilers Low Medium And High Temperature Various Specifications And Sizes

-

Steel Plant use Catalyst